Flare System Ppt

Flare system ppt. Most flaring processes usually take place at the top of stack by burning of gases with the visible flame. The largest load was determined to be the pipeline PRV. Consultancy and Engineering Solutions Feasibility Studies Conceptual Designs Cost Reduction Studies Plant Modifications Debottlenecking Studies Process Flare NetFlare System design studies Depressurizing Models Stack DesignDispersion Models Redundancy requirement of equipment.

The flare system could not handle the load of the expanded process unit. 9 FLARE MONITORING SYSTEM is the monitoring and recording equipment used for the determination of flare operating parameters including higher heating value total sulfur concentration standard volumetric flow rate andor onoff flow indication. In industrial plants flare stacks are primarily.

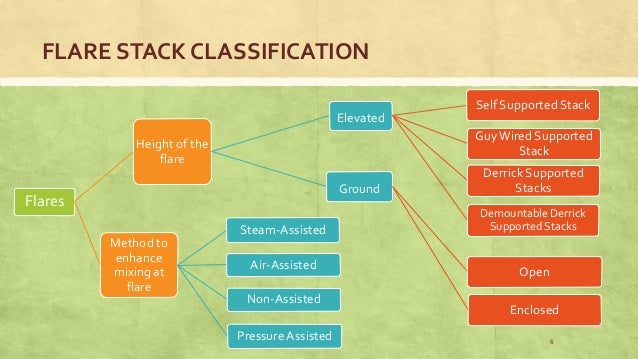

Height of the flame depends upon the volume of released gas while brightness and color depend upon composition. Flaring is a combustion control process in which waste gases are piped to a remote usually elevated location and burned in an open flame in the open air. Winner of the Standing Ovation Award for Best PowerPoint Templates from Presentations Magazine.

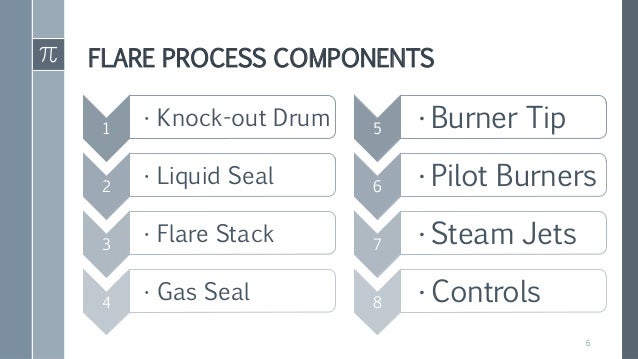

Super Combustion Technologies a well known Gas Flaring System Manufacturers offer Enclosed Gas Flare System Open Gas Flare System Open Bio Gas Flare System Elevated Gas Flare System and Aspirated Gas flaring System at competitive price. A description of and technical information for the refinery flare system and the upstream equipment and processes that send gas to the flare including all associated monitoring and control equipment. It is used to dispose of purged and wasted products from refineries unrecoverable gases.

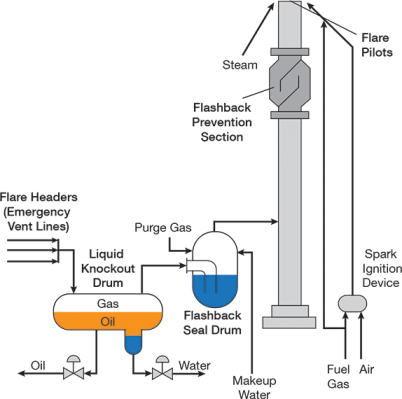

Westlake Two Flare System 4. The team began evaluating various options. Whenever industrial plant equipment items are overpressurized the pressure relief valves provided as essential safety devices on the equipment automatically release gases and sometimes liquids.

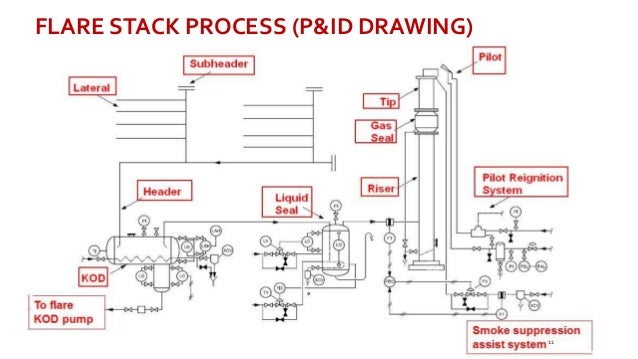

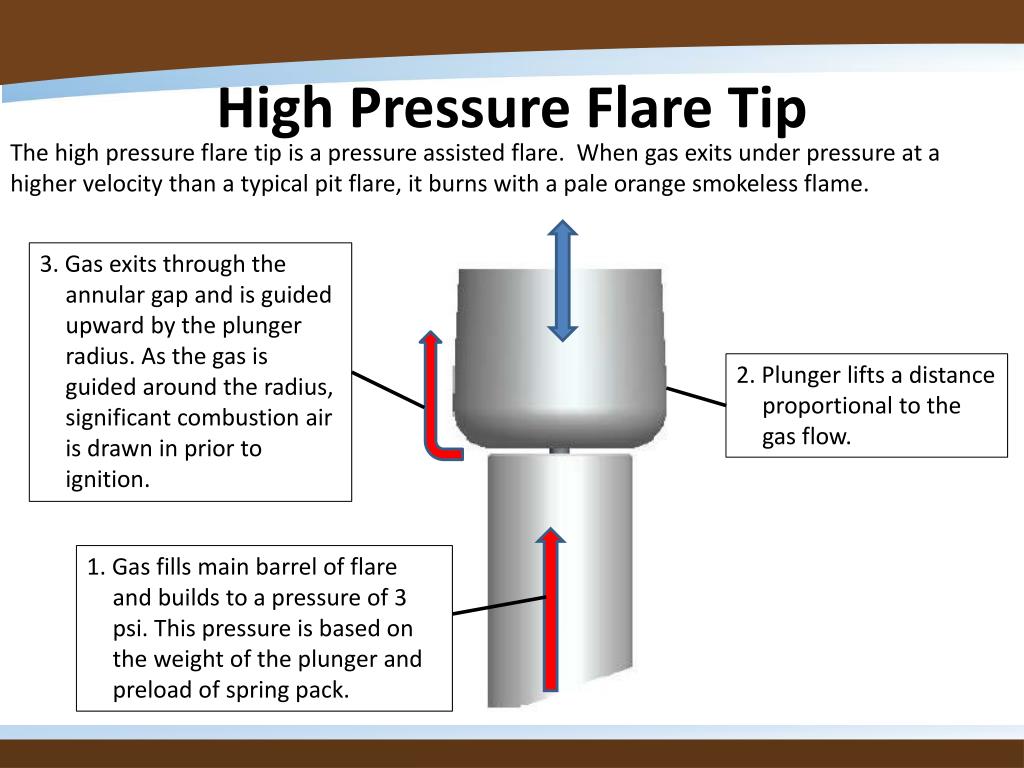

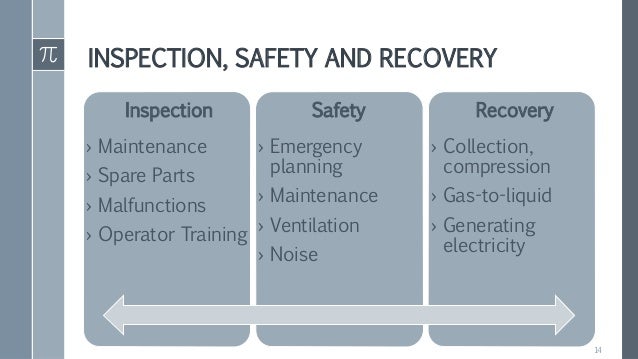

A specially designed burner tip auxiliary fuel and steam or air are used to promote mixing for nearly complete combustion 98. Flare Recovery System Flare hydrocarbon gas recovery systems More common in refineries Less common in chemical plants Flaring generally last preferred destination Any gases sent to flare are lost product for company Flaring has regulatory environmental and community impacts that companies prefer to. 8 FLARE MINIMIZATION PLAN is a document intended to meet the requirements of subdivision e.

The flare system must be purged of air before the pilots are ignited otherwise I there is danger of a severe explosion. PDL PPT Created Date.

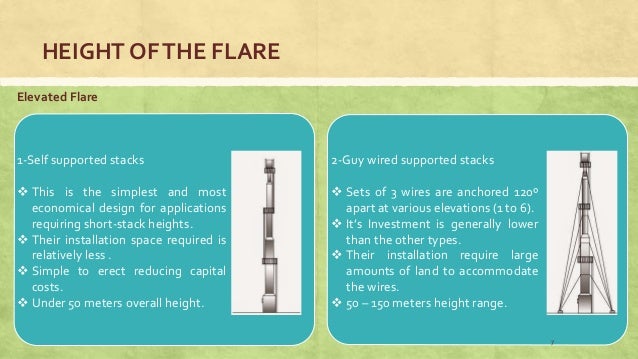

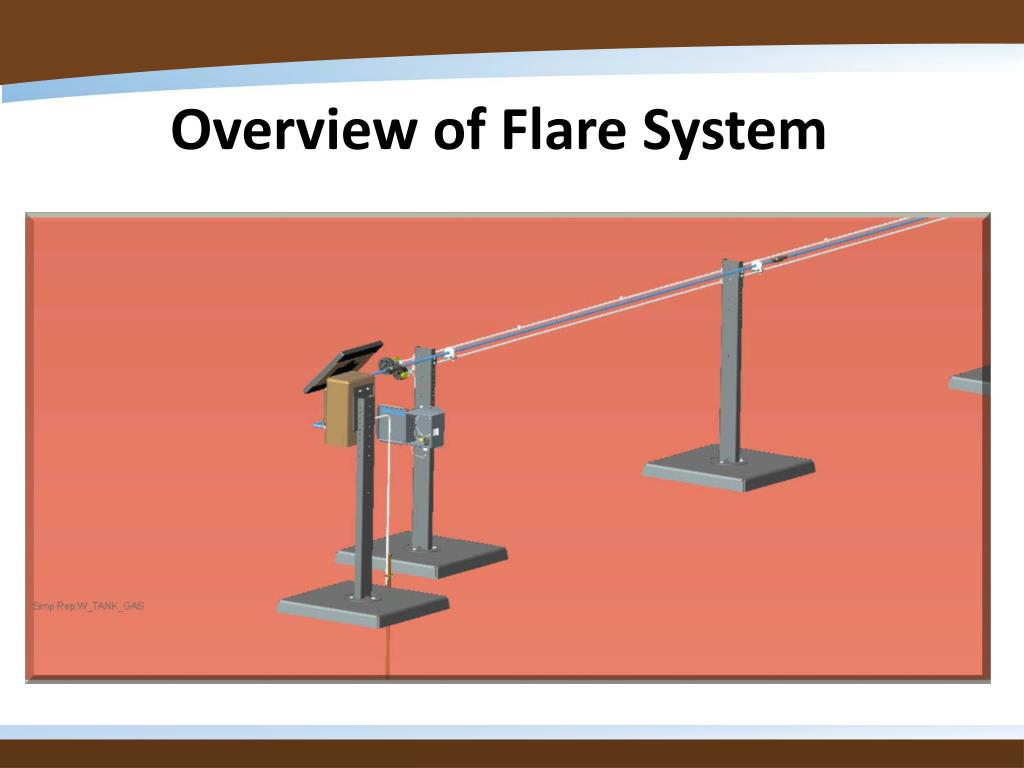

A flare system generally consists of an elevated stack means to maintain burning conditions at the top of stack and means to prevent flashback within the system.

Worlds Best PowerPoint Templates - CrystalGraphics offers more PowerPoint templates than anyone else in the world with over 4 million to choose from. Consultancy and Engineering Solutions Feasibility Studies Conceptual Designs Cost Reduction Studies Plant Modifications Debottlenecking Studies Process Flare NetFlare System design studies Depressurizing Models Stack DesignDispersion Models Redundancy requirement of equipment. It is used to dispose of purged and wasted products from refineries unrecoverable gases. The flare system could not handle the load of the expanded process unit. Environmental Protection Agency FHR Flint Hills Resources FHR AU Flint Hills Resources -. Most flaring processes usually take place at the top of stack by burning of gases with the visible flame. The team began evaluating various options. A description of and technical information for the refinery flare system and the upstream equipment and processes that send gas to the flare including all associated monitoring and control equipment. The largest load was determined to be the pipeline PRV.

PDL PPT Created Date. PDL PPT Created Date. The flare system could not handle the load of the expanded process unit. They are also common at oil or gas extraction sites having oil wells gas wells offshore oil and gas rigs and landfills. One option was to relieve the pipeline pressure to the atmosphere rather than to the flare system. It is used to dispose of purged and wasted products from refineries unrecoverable gases. The Flare is a major part of the pressure relieving system for hydrocarbon processing plants.

.jpg)

Post a Comment for "Flare System Ppt"